SW6SW7

Series Ultrasonic Thickness Gauge

Product Details:

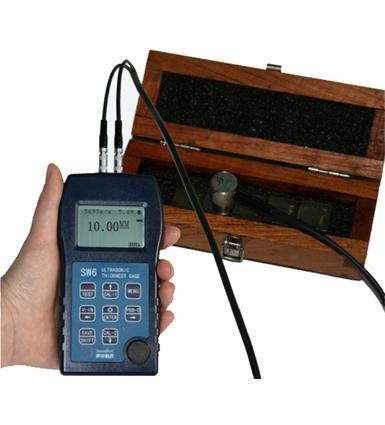

Model SW6 Series Ultrasonic Thickness Gauge

HIGH ACCURACY ULTRASONIC THICKNESS GAUGE

The ultrasonic thickness gauge Model SW6

series are featured as cost-efficiency and designed to make accurate

measurements on steel, cast iron, aluminum, red copper, zinc, quartz glass,

polyethylene, PVC, gray cast iron and nodular cast iron. Thickness measurements

are made from one side of the material with no need to cut the part.

The SW6 series offers various practical

measurement features such as Automatic Probe Recognition that recognizes

transducer types, Field Calibration of all materials Sound velocity range 509

up to18699m/s •

2000 readings memory • Data output to PC • High-Low Limits setting •4 digit LCD

display with settings • Backlight display for dark environment and adjustable.

FEATURES

The ultrasonic thickness gauge Model SW6

series are featured as cost-efficiency and designed to make accurate

measurements on steel, cast iron, aluminum, red copper, zinc, quartz glass,

polyethylene, PVC, gray cast iron and nodular cast iron. Thickness measurements

are made from one side of the material with no need to cut the part.

• Available for gauging various materials

such as metal, glass, plastic, rubber and etc.

• High measurement accuracy and wide range

gauge applications • Suitable for pipe gauging.

• Whole range transducer models are

available for almost all kinds of application, including coarse grain material

gauging and high temperature applications (Max. temperature up to300℃).

•Adaptive probe function built in: Patent

technology of automatic probe recognition: Automatically recognizing for probes

allowing the gage to match with probes made from various probe manufacturers.

• Power on automatic testing function

contributing to measurement accuracy increasing.

• Auto power off detection and customizing

power off configuration.

• Probe Zero function, Sound Velocity Calibration

function.

• 9 velocities built in and programmable.

• Several practical measurement modes

available: Standard Mode, Scanning Mode, Difference Mode, Average Mode, Maximum

limitation Alert Mode, High Temperature Mode(Should be matched with high

temperature probe).

• 8 button keyboard designing for

convenient shortcut operations for Probe-Zero function, One-Point and Two-Point

Sound-Velocity-calibration, as well as numerical adjusting with direction key

control.

• Automatic Data Storage function: group

data storage mode, and storage capacity for each group optional.

• Large data storage capacity, Max. up to

2000 groups.

• Special function of SW6U: USB data

interface communication, easily accomplishing data transferring with PC and

outputting data with “.txt”

• Metric and imperial free convertible.

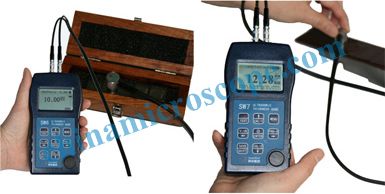

Model SW7 Series Ultrasonic Thickness Gauge

THROUGH COATINGULTRASONIC THICKNESS GAUGE

The ultrasonic thickness gauge Model

SW7series are featured as cost-efficiency and designed to make accurate

measurements on steel, cast iron, aluminum, red copper, zinc, quartz glass,

polyethylene, PVC, gray cast iron and nodular cast iron. Thickness measurements

are made from one side of the material with no need to cut the part.

The SW7series offer various practical

measurement features such as Through coating measurement for gauging thickness

of a painted object without removing the non mental coating • Automatic Probe

Recognition that recognizes transducer types, Field Calibration of all

materials Sound velocity range 509 up to18699m/s • 2000 readings memory • Data output to PC •

High-Low Limits setting •4 digit LCD display with settings • Backlight display

for dark environment and adjustable.

FEATURES

• Through coating measurement for gauging

thickness of a painted object without removing the non mental coating.• Thin

coating mode and thick coating mode

• Available for gauging various materials

such as metal, glass, plastic, rubber and etc.

• High measurement accuracy and wide range

gauge applications •Suitable for pipe gauging.

• Whole range transducer models are

available for almost all kinds of application, including coarse grain material

gauging and high temperature applications (Max. temperature up to300℃).

• Adaptive probe function built in: Patent

technology of automatic probe recognition: Automatically recognizing for probes

allowing the gage to match with probes made from various probe manufacturers.

• Power on automatic testing function

contributing to measurement accuracy increasing.

• Auto power off detection and customizing

power off configuration.

• Probe Zero function, Sound Velocity Calibration

function.

• 9 velocities built in and programmable.

•Several practical modes available:

Standard Mode, Scanning Mode, Difference Mode, Average Mode, Maximum limitation

Alert Mode, High Temperature Mode(Should be matched with high temperature

probe).

• 8 button keyboard designing for

convenient shortcut operations for Probe-Zero function, One-Point and Two-Point

Sound-Velocity-calibration, as well as numerical adjusting with direction key

control.

• Automatic Data Storage function: group

data storage mode, and storage capacity for each group optional. Storage

capacity Max. up to 2000 groups.

• Special function of SW6U: USB data

interface communication, easily accomplishing data transferring with PC and

outputting data with “.txt”

• Metric and imperial free convertible.

SW6 SW7 SPECIFICATIONS:

Thickness MeasurementRange: 0.65 ~400mm(Steel),

0.3~200mm(Glass)

4~80mm(High temperature), 3~50mm(Gray Iron)

Notes: Thickness range depends on material

transducer type, surface condition and temperature.

SW7 Measuring Range (Through Coating):3 mm-20

mm

Material VelocityRange: 509~18699m/s

Measuring Accuracy: ±0.05mm

Display Accuracy:0.01mm/0.1mm

Scanning Rate: 2~20 times/sec.

Scan Velocity: 2times/s~20times/s

Frequency Bandwidths: 1~10MHz

Measuring lower limit of pipes: (Depend on

the probe)

Φ15mm×1.0mm(Probe: 5MHz, Φ10mm)

Φ10mm×1.2mm(Probe: 7.5MHz, Φ6mm)

Display Mode: 128×64 matrix LED

Power supply: 2 AA

Alkaline Batteries

Operating Time: 280 hours typical battery

life,100 hours continuous with backlight on

Operating Temperature Range:-10℃~50℃(Ambient

Environment)

-10℃~300℃(High Temperature Mode)

Gage Size:136 mm×72 mm×20mm

Gage Weight:176g(Including Batteries)

Model

Application

Gauge Range

Diameter

Frequency

Operating Temperature

5MΦ10

General Used

0.8—260mm

10mm

5MHz

-10~+50℃

5MΦ6

Small Pipes

0.75—60mm

6mm

5MHz

-10~+50℃

2MPT-12

Penetrating(Through Coating)

3.0—50mm(cast iron)

12mmor22mm

2MHz

-10~+50℃

7.5MΦ10

High-Accuracy

0.65—100mm(steel)

10mm

7.5MHz

-10~+50℃

ZW5P

High temperature

4.0—80mm

12mm

5MHz

-10~-310℃

Model

Application

Gauge Range

Diameter

Frequency

Operating Temperature

5MΦ10

General Used

0.8—260mm

10mm

5MHz

-10~+50℃

5MΦ6

Small Pipes

0.75—60mm

6mm

5MHz

-10~+50℃

2MPT-12

Penetrating(Through Coating)

3.0—50mm(cast iron)

12mmor22mm

2MHz

-10~+50℃

7.5MΦ10

High-Accuracy

0.65—100mm(steel)

10mm

7.5MHz

-10~+50℃

ZW5P

High temperature

4.0—80mm

12mm

5MHz

-10~-310℃